Aluminum fences are known for their durability and low maintenance, but damage can occasionally occur like anything exposed to the elements. Whether it’s from unexpected weather, miscalculated yard work, or simply wear over time, replacing a damaged aluminum fence panel is a manageable DIY task if you follow the right steps.

In this post, Iron Fence Shop will walk you through exactly how to replace your damaged aluminum fence panels and how to avoid costly and time-consuming replacements in the future.

Replacing Damaged Aluminum Fence Panels Step-by-Step

Whether you’re a seasoned DIY enthusiast or a first-timer, these step-by-step instructions will help you restore your fence to its former glory with confidence. Let’s get started!

Step 1: Assess the Damage

Start by conducting a thorough inspection of your existing fence to determine if the installed aluminum fence panels really need to be replaced. This involves looking for specific indicators for aluminum fence panel replacement. Here are the indicators to look for:

- Structural Integrity: If the aluminum panel is significantly bent or broken, replacement is often the most viable option. Check for bends, breaks, and warps in the metal.

- Corrosion and Rust: Although aluminum is resistant to rust, it can still corrode under certain conditions. Look for any signs of corrosion, such as discoloration or pitting. Extensive corrosion may compromise the panel’s strength, necessitating replacement.

- Attachment Points: Damaged or loose fasteners can indicate that the fence panel is not securely attached, which might require replacement if the damage is severe. Inspect the points where the panel attaches to the fence posts or rails.

- Aesthetic Considerations: If the panel is visibly damaged and detracts from the overall appearance of the aluminum fencing, replacement may be necessary to maintain the fence’s aesthetic appeal.

By carefully evaluating these factors, you can make an informed decision on whether to replace a damaged aluminum fence panel or simply repair it. Significant damages, such as extensive corrosion, may need replacement, while minor damages, such as loose fasteners, can be corrected or repaired.

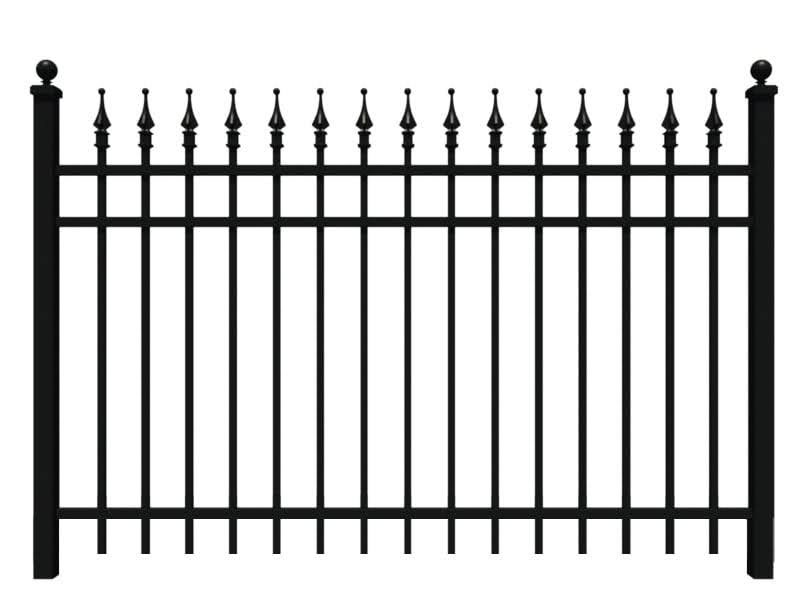

Using high-quality aluminum fences from the start is one of the most effective ways to avoid frequent repairs or full replacements over time. Iron Fence Shop’s Classic Infinity Aluminum fence is the perfect choice because it maintains its structural integrity and appearance with minimal upkeep.

| Classic Infinity Aluminum® Fence |

|

|

| SEE DETAILS |

Step 2: Gather Your Tools and Materials

Once you have determined that you should replace your damaged aluminum fence panels, gather the right tools for a smooth and efficient replacement process. Here is a list of essential tools:

- Drill: For removing and securing screws

- Level: For aligning your new aluminum fence panels

- Measuring Tape: For getting accurate measurements for cutting and positioning panels

- Pliers: For bending or adjusting small metal components

- Saw: For cutting panels to the desired size

- Screwdriver Set (with Phillips and flathead types): For tasks that require more precision

- Wrench Set: For tightening bolts and nuts

Having the right materials is just as crucial for a smooth and efficient aluminum fence replacement process. Here is a list of materials to prepare:

- Replacement Panels: Make sure to get panels that match your entire fence in color, size, and style.

- Fasteners and Screws: Get those specifically designed for aluminum fencing because they are usually rust-resistant and provide a more secure hold.

- Touch-Up Paint or Sealant: Use a color-matched touch-up paint to cover scratches or exposed areas that might occur during installation, and the sealant to enhance durability against weather elements.

By having these tools and materials ready, you can replace your aluminum fence panels with confidence, knowing that you are well-prepared to handle any challenges that may arise. This preparation not only saves time but also ensures that the final result is both functional and visually appealing.

| Safety is Paramount: Add safety goggles and gloves to your list of essentials. They help protect against injuries from flying debris and sharp edges. |

Step 3: Remove the Damaged Panel

To safely remove a damaged aluminum fence panel without causing further damage, follow a systematic approach that ensures both the integrity of the remaining structure and your personal safety. Here’s how to do it:

- Inspect the Panel and Connections: Examine how the damaged panel is attached to the fence. Look closely for bolts, clips, screws, or other fasteners connecting it to the fence posts.

- Remove Fasteners Carefully: Use the power drill, screwdriver, or wrench to unbolt or unscrew the fasteners holding the panel in place.

- Check for Hidden Connections: If the damaged panel doesn’t come loose right away, check for hidden clips, missed fasteners, or interlocking connections. Many aluminum fences use special connectors that you may need to release gently.

- Gently Remove the Panel: Carefully lift and wiggle the panel free from the fence posts. Take your time to avoid forcing it out and damaging other components.

By following these steps, you can safely and efficiently remove a damaged aluminum fence panel, preparing the area for the installation of a new panel.

| Protect Existing Posts and Panels: Before completely removing the panel that needs to be replaced, consider placing a soft cloth or padding between your tools and the entire fence to avoid scratching or denting neighboring sections. Be extra cautious around painted surfaces. |

Step 4: Install the New Panel

Proper alignment and secure fastening are key to maintaining the fence’s strength and appearance. Follow these steps to ensure your replacement panel fits perfectly and holds up over time:

- Position the New Panel in Place: Set the panel between the existing fence posts. Use the measuring tape to check that it is centered and evenly spaced. Aim for a snug, balanced fit for stability and visual appeal.

- Check for Level and Alignment: Use the level to verify that the panel is perfectly straight horizontally and vertically. This reduces stress on the structure over time and ensures the fence looks uniform.

- Drill Pilot Holes: Before inserting screws, drill pilot holes into the ends of the panel rails and into the posts. This prevents the aluminum from cracking or warping and ensures a smoother, more controlled installation.

- Secure the Panel to the Posts: Attach the panel using the appropriate fasteners or screws, starting at one end and working your way across. Tighten each screw firmly, but avoid over-tightening, which can damage the material or warp the panel.

These steps ensure your new aluminum fence panel is properly aligned and securely installed, contributing to the overall durability and appearance of your entire fence.

Avoiding Costly and Time-Consuming Replacements

Avoiding full panel replacements starts with smart choices and proactive care. By investing in quality materials, performing even just minimal maintenance, and using proper installation methods, you can extend the life of your aluminum fence and avoid unnecessary expenses.

Use High-Quality Aluminum Fence Panels

Not all aluminum fencing is created equal. Though aluminum provides natural corrosion resistance, environmental exposure such as moisture, salt, and UV rays can still cause degradation without a proper surface treatment.

This is why Iron Fence Shop uses a high-performance TGIC polyester powder coating on every Infinity Aluminum® fence panel. This durable finish ensures long-term resistance to chipping, corrosion, and fading, even in harsh outdoor climates.

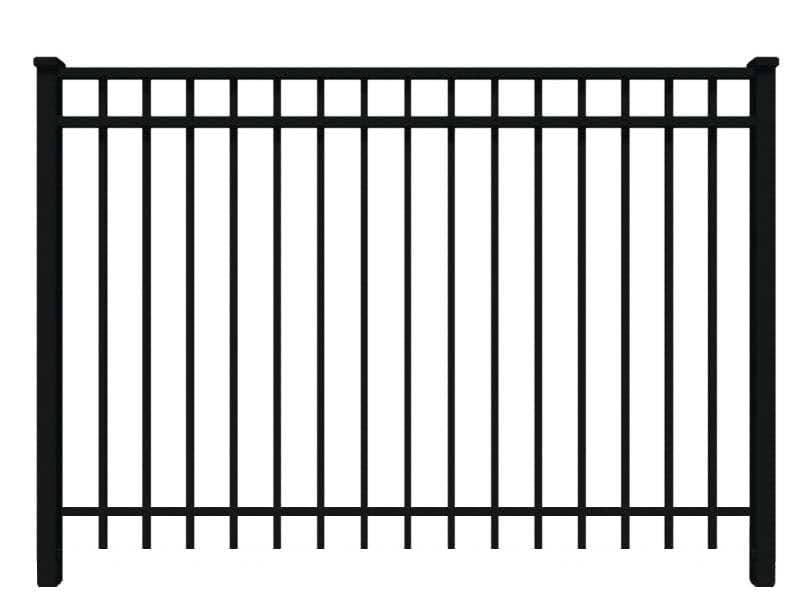

For projects where safety and versatility matter just as much as durability, the Smooth Top Infinity Aluminum® fence is an ideal choice.

| Classic Infinity Aluminum® Fence |

|

|

| SEE DETAILS |

Perform Regular Maintenance on the Entire Fence

Establish a maintenance routine to help keep your aluminum fence in excellent condition and prevent potential issues. Here are some key maintenance tasks:

- Clean the Fence: Regularly remove dirt, grime, and any buildup. Use a mild detergent mixed with water and a soft cloth or sponge to clean the surface gently.

- Inspect for Damage: Periodically check your fence for signs of damage, such as scratches, dents, and loose fasteners.

- Trim Vegetation: Regularly trim overgrown plants and vines that come into contact with your aluminum fence to prevent them from scratching or bending your panels.

Performing regular maintenance on your aluminum fence is not just about extending its lifespan and preserving its appearance. It’s also a matter of staying in compliance with local regulations. For example, the city of Temple Terrace, Florida, states:

All fences and walls, including but not limited to chain link, wood, brick, and masonry construction, shall be kept in good repair, sound structural condition, and shall provide a neat appearance in keeping with the character of the neighborhood.

Maintaining your aluminum fence protects your investment and ensures full compliance with local ordinances.

Avoid Damage During Replacements

When replacing a damaged aluminum fence panel, it is crucial to avoid causing harm to the surrounding parts of the fence. Here are some tips to ensure the integrity of your entire fence remains intact during the replacement process:

- Handle Tools Carefully: Use tools with rubberized grips or padded handles to reduce the risk of slipping or accidentally striking other parts of the fence.

- Clear the Work Area: Get rid of debris or obstacles that could cause you to trip or lose balance. Consider setting up barriers so others can maintain a safe distance while you work.

- Employ a Second Pair of Hands: Get help from another person if possible. They are particularly helpful in lifting larger panels and keeping them steady and secure during installation.

Work with Reliable Aluminum Fence Panel Experts

Choose a reliable aluminum fence manufacturer to help avoid costly replacement down the line. With Iron Fence Shop, you are not just picking panels that look good. You are also investing in materials, craftsmanship, and customer support built to last.

With over 60 years of combined fence experience, we know our products inside and out. We can help suggest products, compare our products to competitors, and answer all kinds of questions, including those involving installation. This one-on-one approach service is one of the biggest reasons our customers recommend us to others.

Working with dedicated fence experts ensures you get products thoughtfully engineered and backed by people who know fencing deeply.Make Smart Fence Moves Today

Replacing a damaged aluminum fence panel may seem like a challenge at first, but with the right preparation, tools, and guidance, it’s a project any DIYer can tackle. Partner with trusted experts to prevent future damage and enjoy a fence that looks great and performs well for decades.

Upgrade your fence today. Talk to the fence experts at Iron Fence Shop and find the ideal combination of durability, design, and customization for your next fence project.

Free Shipping over $5,000

Free Shipping over $5,000

15 Years in Business

15 Years in Business

18mo No Interest Financing

18mo No Interest Financing